UAV applications

Why MINDECO drone applications are attracting great attention

UAVs (Unmanned Aerial Vehicles) have great potential for a wide variety of applications which can reduce costs and risks involved with our current services and are helping to give added value to customers. As MINDECO is a mining specialist, we have been applying this technology to mainly mining fields so far. Some of these applications are as follows:

1. Photographic monitoring of mining facilities and abandoned mines,

2. Photographic surveying for 3D modeling for geological structures and slope failure monitoring,

3. Volume estimation of heaped lightweight aggregate for affiliate companies,

4. Drone-borne magnetic surveys for mineral exploration, and

5. Super detailed topographical surveys by LiDAR for tailings dam safety and detailed terrain surveys.

The following are some examples of applications.

Monitoring aging mining facilities

Photographic monitoring is a very effective approach for observing aging mining facilities, due to its cost effectiveness and fast service.

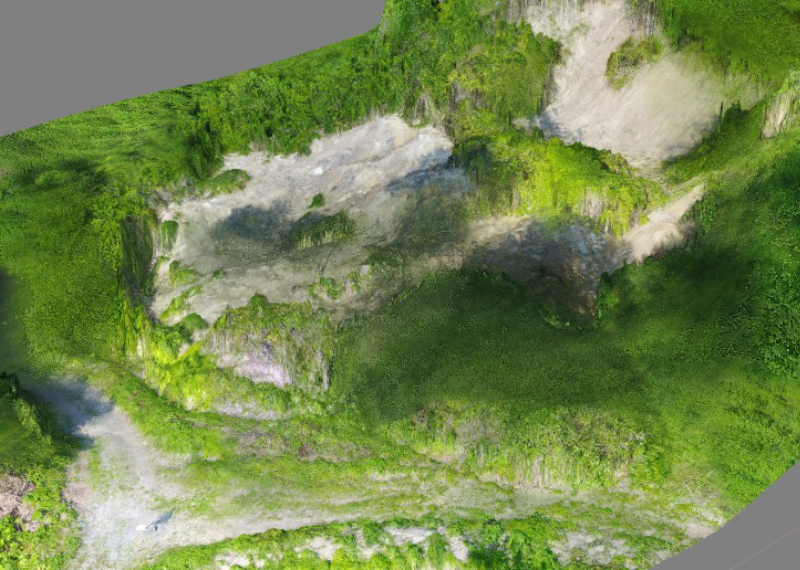

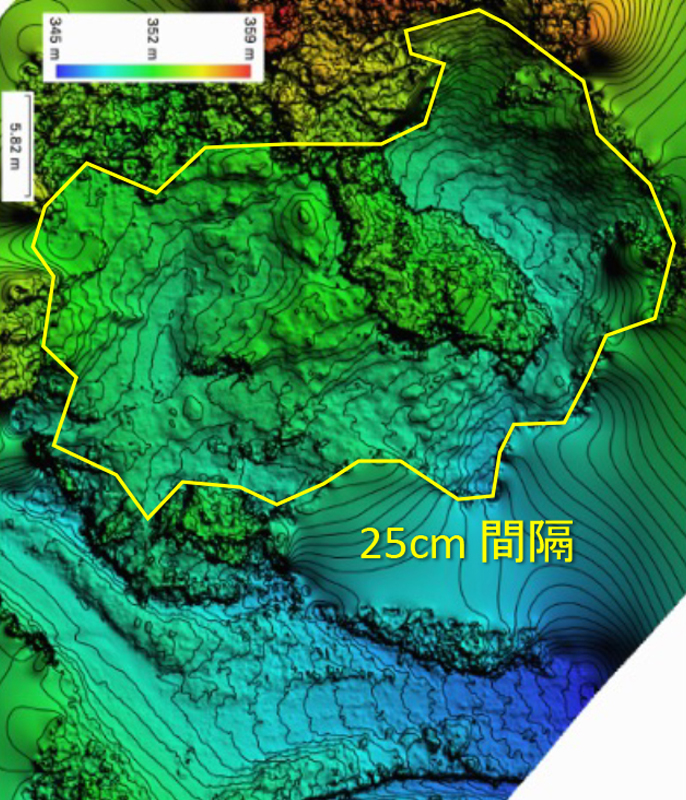

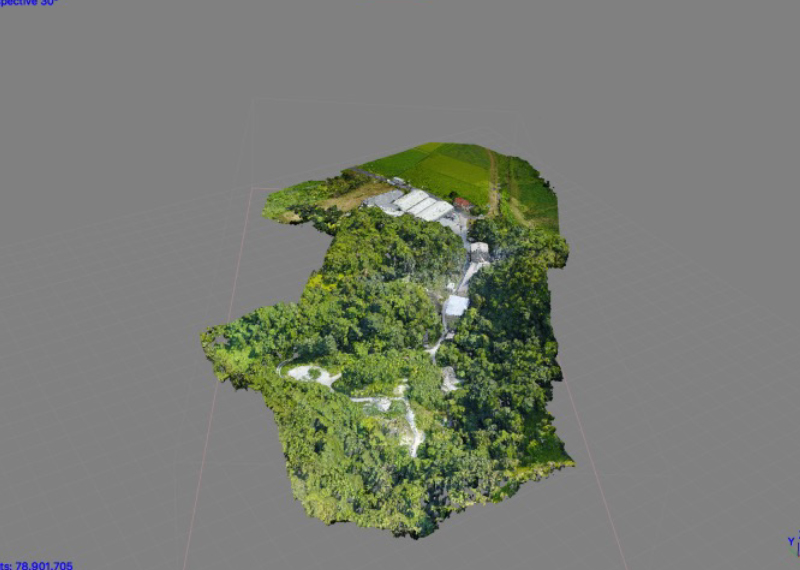

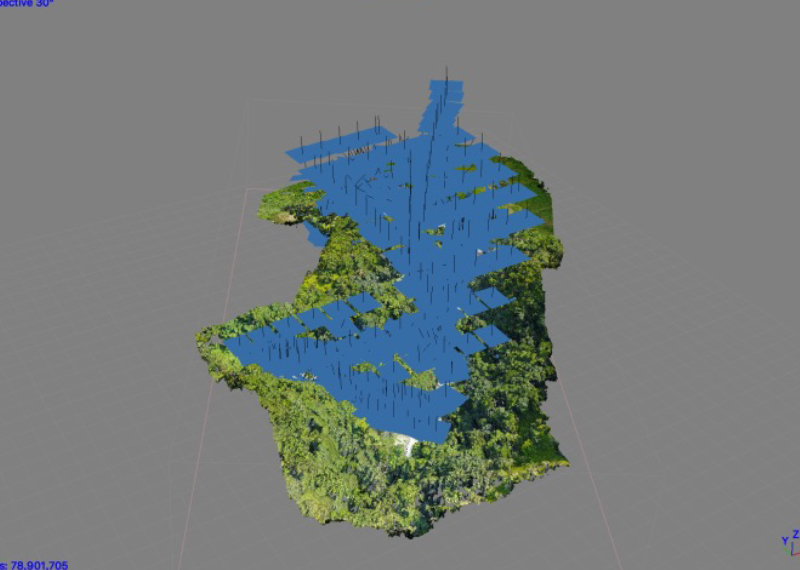

Creating 3D models

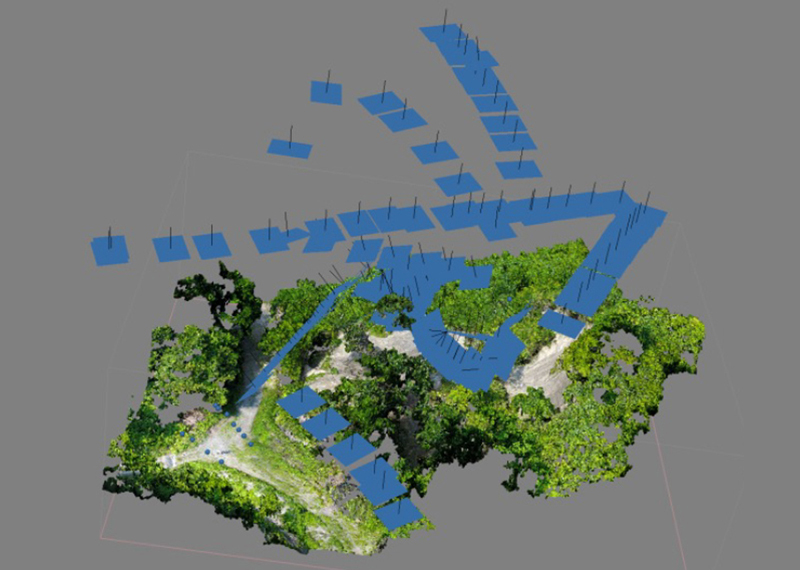

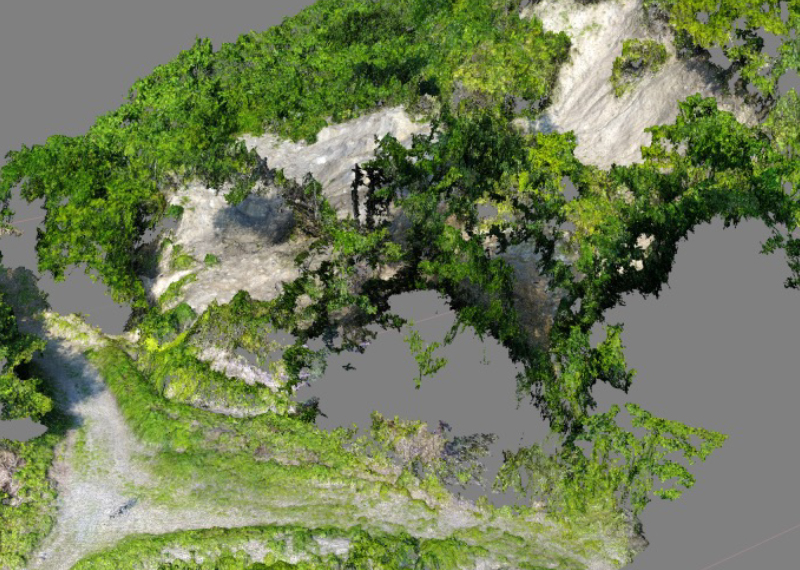

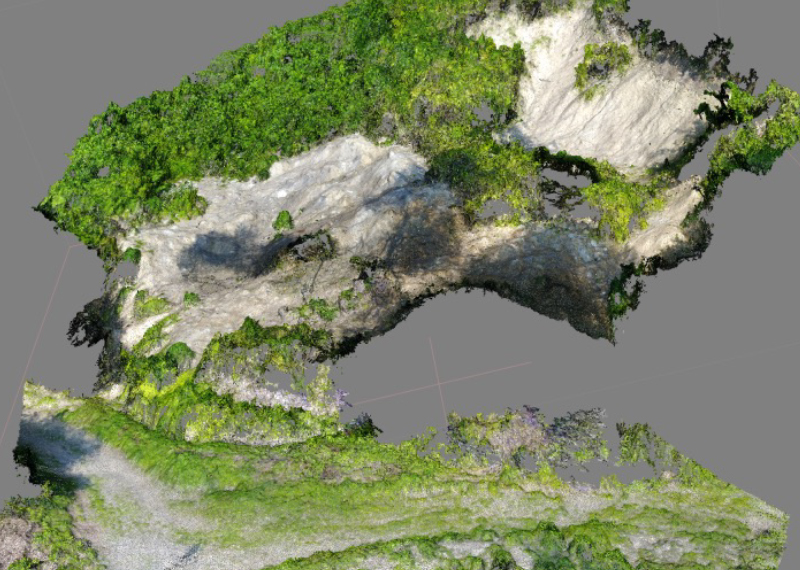

An example of creating 3D models from aero-photography using the SfM (Structure from Motion) procedure in a slope failure area. Since drone camera shooting can be done not only for ordinary photographic surveys which use mainly vertical shooting angles to create topographic models, but also can shoot footage from various other angles, we can create 3D models of topographical features even if they are covered by canopies.

mine site

failure area

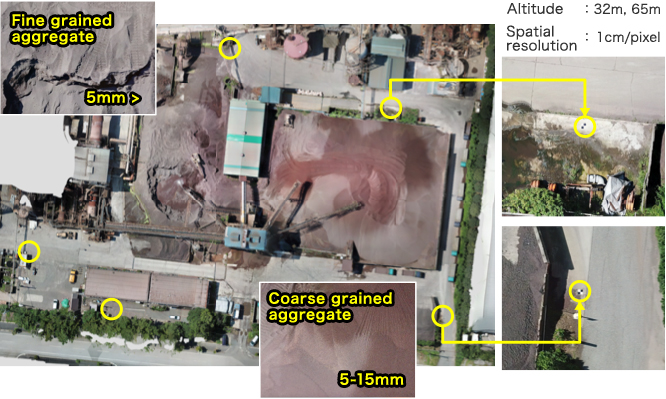

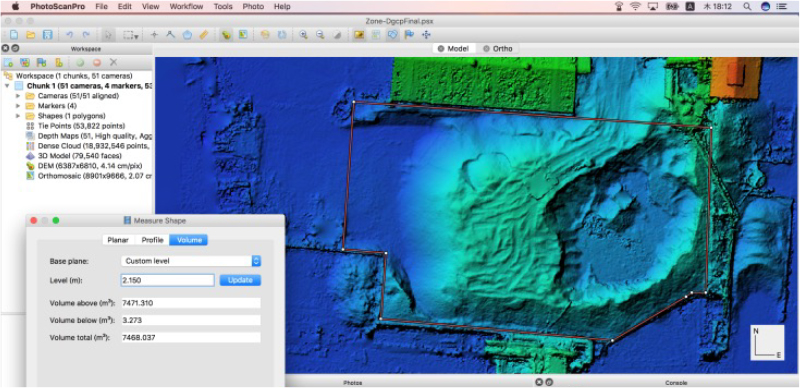

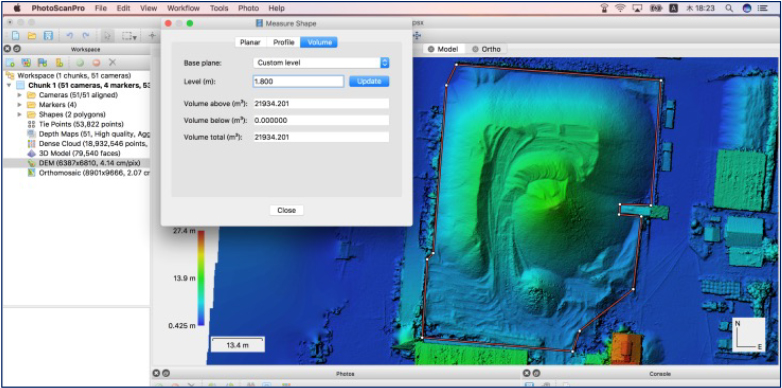

Estimating the volume of heaped lightweight aggregate

Volume estimation of heaped lightweight aggregate

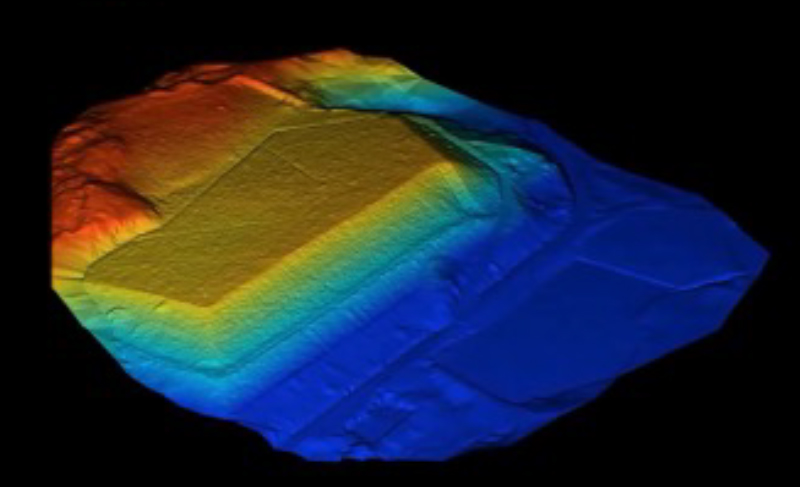

We have also applied aero-photographs for estimating the volume of heaped lightweight aggregate. This is also used with the SfM procedure to create 3D models. Here we need to set up several GCPs (Ground Control Points) to take photographs. RTK-GPS is used to take precise surveys, and the GCP points are used as reference points.

This program creates point clouds after SfM processing, deletes unnecessary reflected points from cranes, belt-conveyers, etc., and then constructs DEM or TIN. We can then calculate the volume of the heaped lightweight aggregate.

3D modeling of slopes

Compiling a series of photos taken from a camera mounted on a drone using the SfM procedure enables us to create 3D modelling for various kind of targets.

The 3D models can be used for geological analysis using post processing and have different values from ordinary footages.

The upper 3D model shows the turbidite structure of a rock cliff in Geopark in Chichibu. The lower model shows all of MINDECO’s Zeolite mines in the Iwami district. Both of the models were compiled from more than 150 photographs.

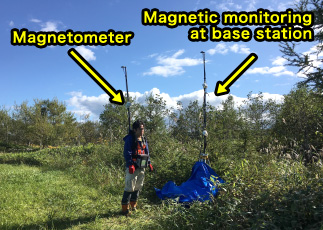

Airborne geophysical surveys

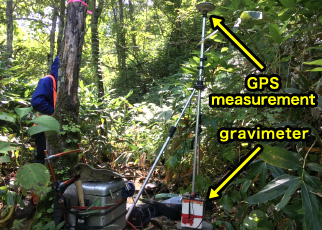

On-ground geophysical surveys are sometimes very tough to deal with obstacles such as vegetation, animals living in forest and bush and so on. So, airborne geophysical exploration using helicopters and/or other aircraft has been utilized. However, there are various kinds of issues associated with that such as added expenses, the need for a temporary heliport, difficulties with low altitude flights and so on. Thus, this method has been used in relatively limited areas. We believe drone airborne geophysical surveys may enable us to form a bridge between on-ground and ordinary airborne surveys. MINDECO applied full-fledged drone airborne magnetic surveys to mineral exploration in 2017 and demonstrated their effectiveness in tough field survey areas.

Broad area covered with 50% Kuma bamboo bush Bears, deer, ticks,…

Kuma bamboo grass more than 2 meters high

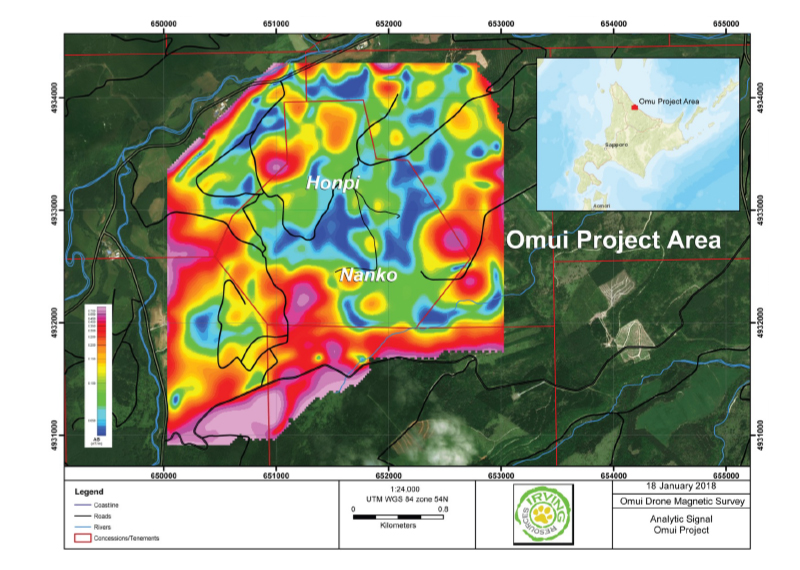

Airborne-magnetic surveys

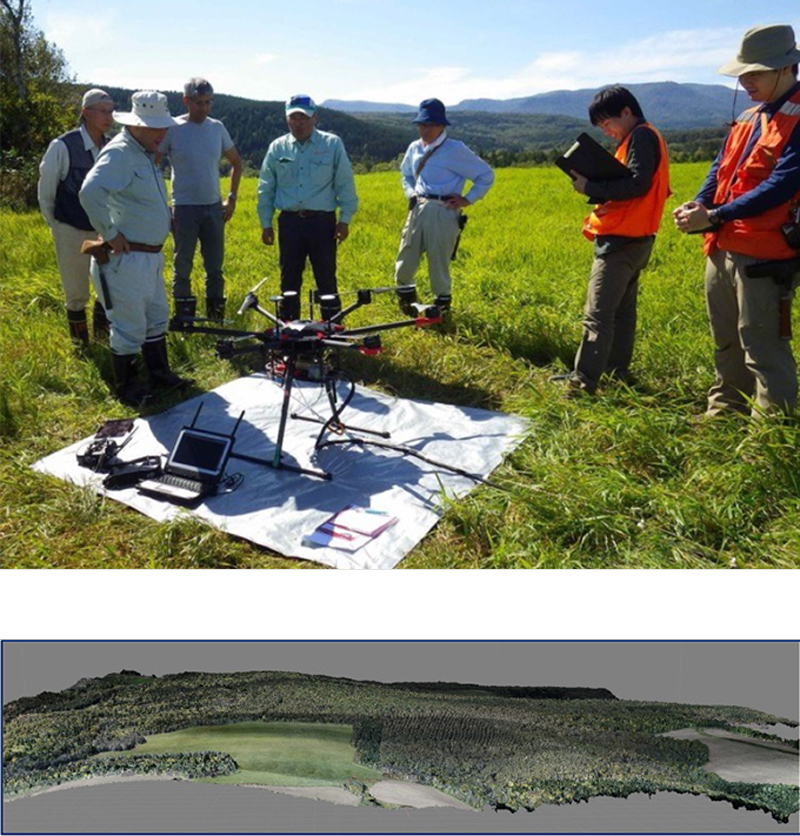

MINDECO conducted airborne-magnetic surveys for mineral exploration in the northeastern part of Hokkaido facing the Sea of Okhotsk. We loaded a potassium magnetometer and data recording and transfer circuits onto a DJI Matrice 600 Pro.

Hovering potassium magnetometer

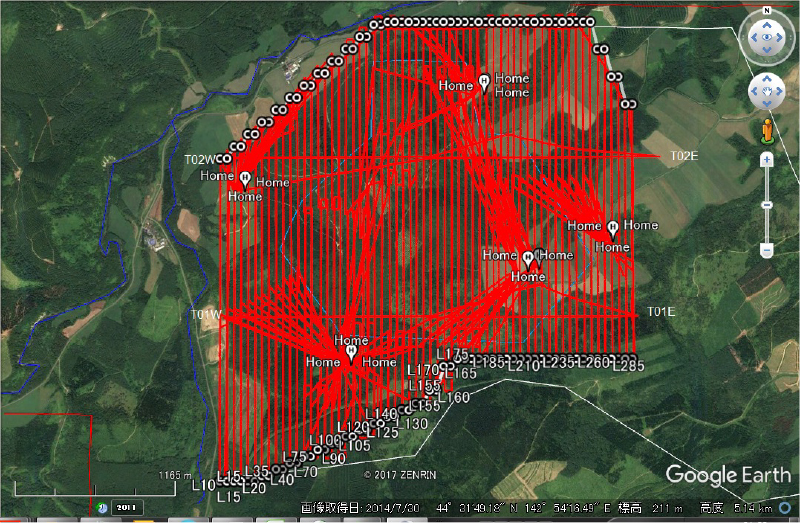

For this survey, we established a flight operation approach with stable terrain clearance

Total flight distance of magnetic surveys in 2017 and 2018 has exceeded 600 km. The following are some examples of flight lines.

MINDECO conducted airborne magnetic surveys using drones at a height of 70m in 2017. The results had a higher resolution than those of ordinary airborne surveys by helicopter or aircraft. This approach helps to drastically reduce the survey period compared with on-ground surveys.

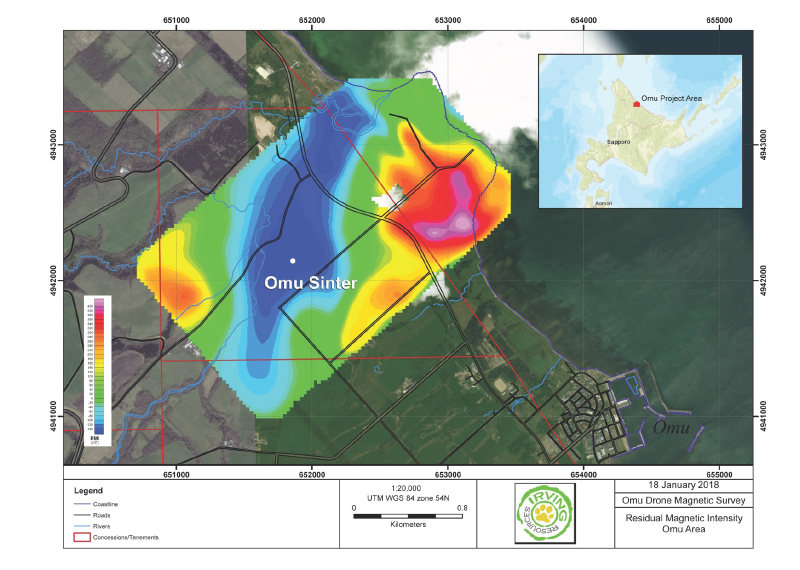

The figure on the left below depicts residual magnetic anomaly after height reduction, and identifies large magnetic changes around graben structural area. The right figure represents the result by Analytic Signal, and magnetic features near mineral occurrences. MINDECO has now started lower flight service of 40m above terrain, which can provide magnetic anomalies with higher resolution.

<References>

N. Shiga, H. Harada, and K. Wada (2019): A case study on the application of a magnetic survey using magnetometers carried by multicopter-type drones, Japan Geoscience Union Meeting (JpGU) 2019, STT44-01.

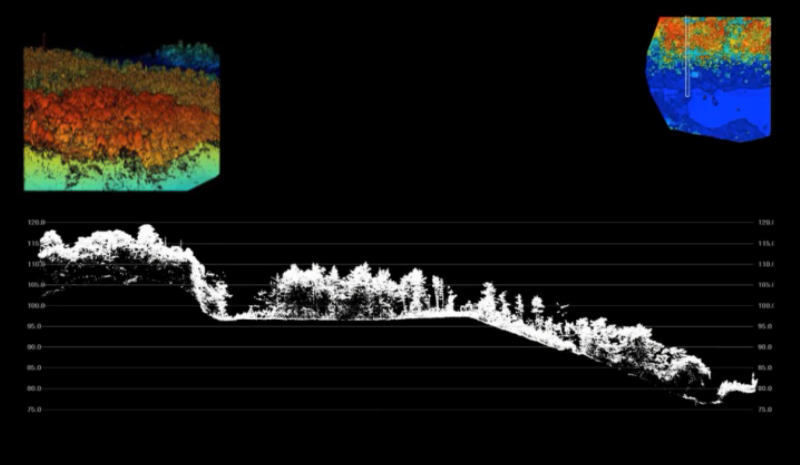

Ultra-high-precision surveys by LiDAR measurements

In late 2017, MINDECO launched its LIDAR (Light Detection and Ranging) measurement service for clients in order to take super detailed measurements of ground surfaces. Affiliated companies have also used these services for such tasks as monitoring the safety of tailings dams. In May 2018, we successfully applied LIDAR to mineral exploration to identify sinter zones from detailed topographical features covered by trees and bushes. These measurements were then used to identify target zones.

ground surface, trees, grass,

artificial structures and so on.

after removal of vegetation

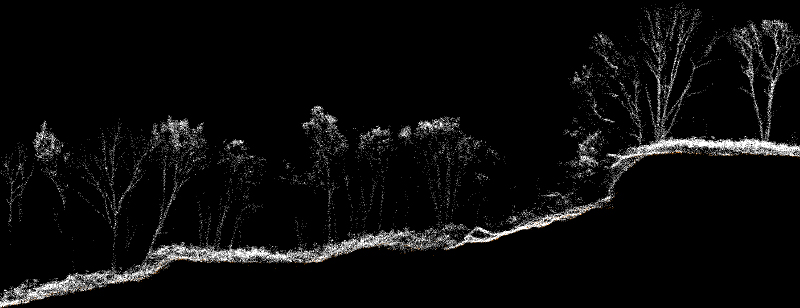

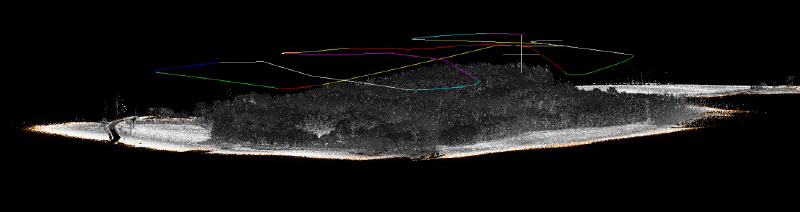

Point cloud in a survey area from a low angle point of view shows vegetation, grassland, roads and power poles with the LiDAR flight route. In this area, flight height is a constant 30m above the terrain.

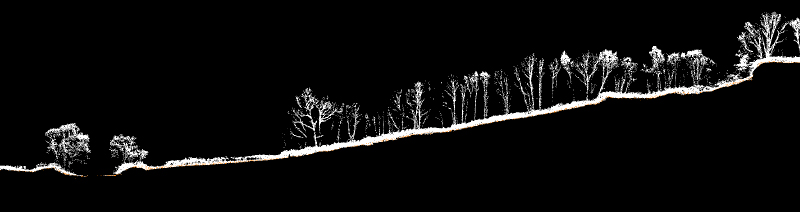

This slice of point cloud with a width of 5m depicts streams, trees, and dense Kuma bamboo bush. Topographical features can be clearly identified.

This slice shows an outcrop near a cliff, bounding rocks and fallen trees with Kuma bamboo bush.